IoT Based Energy Monitoring System Design Using Microcontroller (MCU)

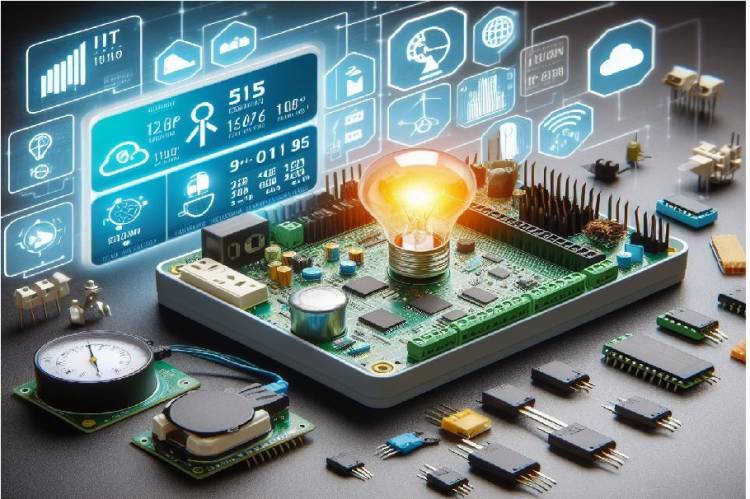

Energy monitoring systems are critical for monitoring and optimizing energy consumption in daily life and industrial environments. In this article, we will discuss the steps to design an IoT-based energy monitoring system using microcontroller (MCU).

1. Determination of Requirements

The first step is to determine the requirements of the design. These requirements include factors such as the energy parameters to be measured, measurement sensitivity, monitoring period and system scalability. For example, power factor, voltage and current measurements may be important for a home energy monitoring system.

2. Sensor Selection

It is critical to select sensors that meet the specified requirements. Current and voltage sensors are types of sensors commonly used for energy monitoring systems. Attention should be paid to features such as sensitivity, accuracy and response time.

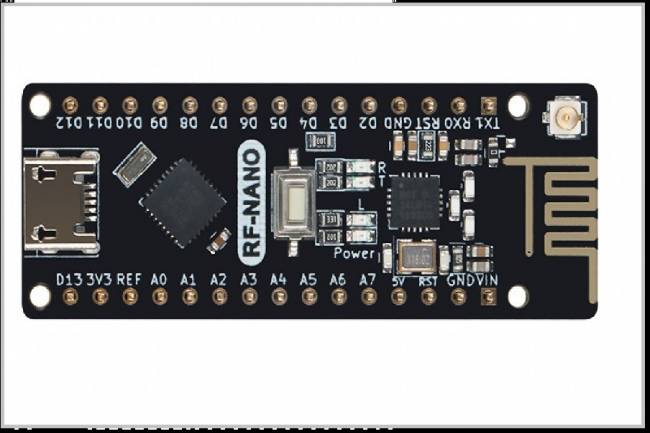

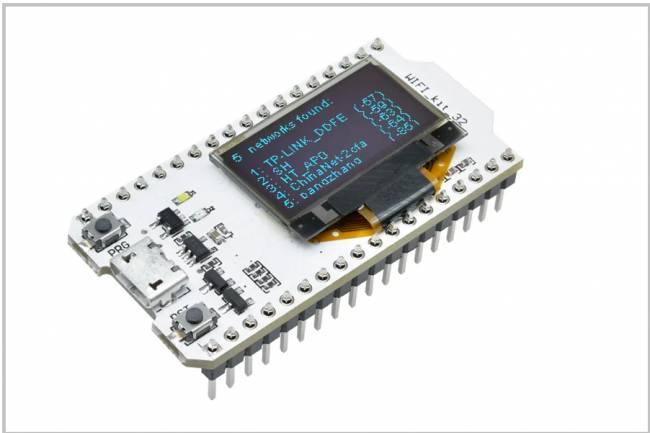

3. Microcontroller Selection

MCU selection is a key decision that affects system performance. The MCU is an important component that will process and transmit sensor data and run energy monitoring algorithms. Powerful, energy-efficient MCUs such as the ARM Cortex-M series or ESP32 are generally preferred.

(Learning Microcontroller Chips: Why Is It Necessary?)

4. Data Transmission Protocol

An appropriate communication protocol must be selected to ensure communication between the MCU and sensors. Besides lightweight IoT protocols such as MQTT or CoAP, security protocols such as TLS/SSL should also be considered to transmit energy data securely.

5. Power Management

The energy monitoring system must generally operate continuously, so power management is important. The MCU's ability to switch to low-power modes and energy-saving algorithms should be evaluated at this stage.

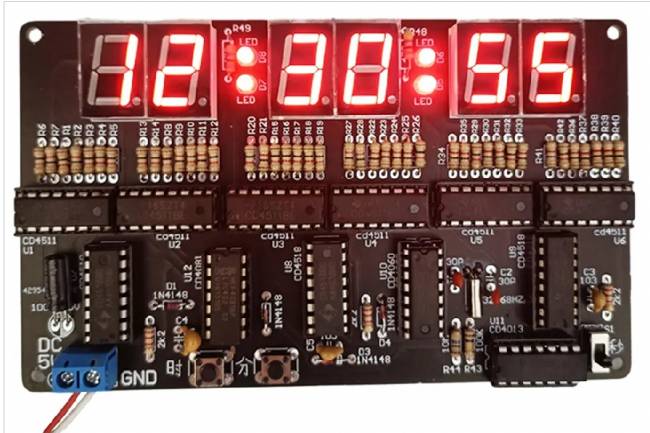

6. Data Analysis and Visualization

Analyzing the collected data and visualizing it on a user-friendly interface is important for the usability of the system. At this stage, technologies such as databases, cloud platforms and web-based interfaces can be integrated.

7. Security

Energy monitoring systems often contain sensitive data, so security is of paramount importance. System security must be ensured by using data encryption, access control and secure communication protocols.

8. Prototyping and Testing

A prototype containing the selected MCU, sensors, and communication protocols must be created and tested in real-world conditions.

Here are a few examples of current and voltage sensors commonly used in energy monitoring systems:

Current Sensors:

1. Current Transformer Sensors:

Current transformers are sensors that convert high currents into low currents and are used for monitoring purposes. They are generally used for AC current measurement.

2. Hall-Effect Current Sensors:

Hall sensors are sensors that measure a current in a magnetic field. These sensors are often used in industrial systems and provide accurate results in monitoring applications.

3. Shunt Resistance Current Sensors:

A shunt resistor is a resistor through which current flows, and the voltage dropped on it is used to measure the current. This type of sensors is widely used for accurate measurement of low currents.

Voltage Sensors:

1. Resistance Divider Voltage Sensors:

Voltage divider circuits generally consist of resistors that reduce the voltage value to a low level. These sensors are used in high voltage systems and reduce the measured voltage to a level that can be processed by the MCU.

2. Capacitor Voltage Sensors:

Capacitors can be used to measure voltage. The voltage across the capacitor is determined by the charge stored in the capacitor.

3. Magnetic Potentiometer Voltage Sensors:

Magnetic potentiometers measure voltage using a sensor that changes the position of a magnet. These sensors generally provide accurate and long-lasting measurements.

These sensors are just a few of a range of sensors used in energy monitoring systems. The selection should include evaluating whether the sensor to be used meets the application requirements and factors such as sensitivity and accuracy.

Code names of current and voltage sensors with examples:

Current Sensors:

1. Current Transformer Sensors:

Code Name: ACS712

Description: ACS712 is a current transformer sensor that converts high currents into low currents and is generally used for AC current measurement.

2. Hall-Effect Current Sensors:

Code Name: ACS758

Description: ACS758 is a current sensor that works using a Hall sensor that measures a current within a magnetic field. It is widely used in industrial systems.

3. Shunt Resistance Current Sensors:

Code Name: INA219

Description: INA219 is a current sensor that measures the voltage dropped on the shunt resistor and is used for accurate measurement of low currents.

Voltage Sensors:

1. Resistance Divider Voltage Sensors:

Code Name: ZMPT101B

Description: ZMPT101B is a voltage sensor that reduces the voltage to a low level using a resistor divider circuit and is generally used in high voltage systems.

2. Capacitor Voltage Sensors:

Code Name: ZC-020

Description: ZC-020 is a voltage sensor that measures voltage using capacitors. It measures the voltage determined by the charge stored on the capacitor.

3. Magnetic Potentiometer Voltage Sensors:

Code Name: AS5048A

Description: AS5048A is a sensor that measures voltage using a magnetic potentiometer. Provides accurate and long-lasting measurements.