What is solder? What are the types?

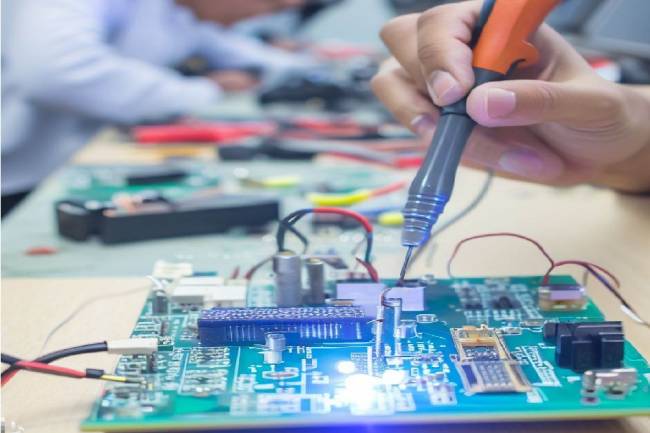

Solder is a material used to join or join two or more metal surfaces. This process is used in many applications where metal parts need to be fixed, made conductive connections or metal components must be joined together. Solder consists of a special alloy with a low melting point, and this alloy is called "solder".

The main components in the structure of the solder can be:

1. Base Metal: The main component of the solder alloy consists of metals. While tin (Tin) and lead (Pb) are traditionally used, lead-free solders are preferred due to environmental and health concerns. Today's common solders consist of a mixture of tin and other metals.

2. Flux: May contain flux, a chemical substance that helps metals bond better by reducing oxidation and surface tension during the brazing process. Flux basically removes oxide layers and makes soldering metal surfaces easier.

Solder types can vary depending on the application to be used, the type of metals and requirements. For example, lead-free solders do not contain lead and are often used for soldering electronic components. The soldering process includes certain steps such as cleaning, heating, applying solder, and cooling the surfaces.

Solder is an important material that is widely used in the electronics industry, metalworking, automotive industry and many other fields.

What is Solder Cream?

The term "cream solder" refers to a type of soldering material used for soldering operations. This solder usually comes in a soft consistency like paste or cream and is used to make soldering easier and more organized.

Solder paste is a special form of solder alloy (usually a mixture of tin and other metals). This form allows the user to apply more easily and to apply the soldering material to the metal surfaces properly. Cream solder provides a more flexible use than traditional brazing wires or rods and can be preferred for precision soldering operations.

The content of solder paste may vary depending on the application and brand to be used, but it basically consists of a mixture of tin and other metals. It may also contain flux to clean the surface and reduce oxidation during the brazing process.

Solder paste is especially useful for delicate and small operations such as soldering electronic components. It provides better control during the soldering process and you can spread the soldering material evenly on the desired surface.

What is Flux?

Flux or fluxing agent is a chemical or component used during metal brazing operations. Soldering is a method used for cleaning metal surfaces and joining metals together. Flux is used to facilitate and enhance this process. Here are the main functions of the flux:

1. Removing the Oxide Layer: Metal surfaces oxidize over time and this oxide layer can prevent efficient brazing. Flux removes this oxide layer and makes metal surfaces clean and solderable.

2. Reducing Surface Tension: By reducing the surface tension between metal surfaces, it allows the solder to spread on the surfaces better. This creates a stronger and stable solder joint.

3. Anti-oxidation: Flux prevents further oxidation of the metal during brazing. This improves the quality of the soldering process and makes the end product more reliable.

Fluxes can be of different types and there are varieties suitable for different applications. For example, fluxes used for soldering electronics are specially designed to allow operation at lower temperatures and leave no residue during soldering of electronic components. Also, water-based fluxes may be a more environmentally friendly option when considering cleanliness and environmental factors.

Flux plays an important role in the soldering process and choosing the right flux is a critical part of creating a successful solder joint.